Founded in 1991, Tayang is one of the largest manufacturers of input devices in the world. 90% of our products are manufactured using high-quality silicone materials that we develop and produce ourselves. We own and operate two high efficiency production facilities to keep up with the demands of our valued customers. These well-equipped factories are responsible for an output of around 200 million silicone products each year. We specialize in the production of consumer electronics, computer keypads, mobile phone parts, automobile components, daily necessities, and much more. We work with some of the largest manufacturers in the world and would love to do business with you.

-

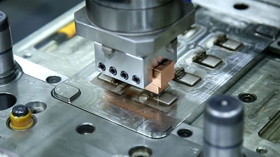

- Liquid Silicone Rubber Injection Molding With extensive experience in liquid silicone rubber injection molding services, Tayang offers an array of custom LSR products, including silicone rubber buttons, keypads, housings and other silicone rubber parts.

-

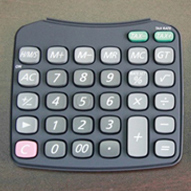

- Silicone Rubber Compression Molding With nearly 30 years of experience,Tayang has the expertise necessary for providing an outstanding silicone rubber compression molding service. We offer small-volume silicone rubber compression molding products, including keypads, gaskets, key fobs, decorated plastic parts and more.

-

- Liquid Silicone Rubber Overmolding The silicone overmolding (also called two shot molding) is a process in which the silicone rubber is molded over a plastic or metal substrate. This process is designed to improve product quality and performance, simplify assembly, increase airtightness, and ensure waterproof, dustproof ...

-

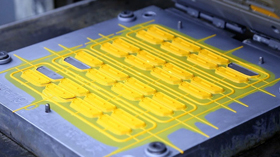

- Bonding Assembly Due to the characteristics of snap on metal domes, keypads with bonded metal domes produced by us feature a fast response and a better user experience compared to other keypads with PU domes.

-

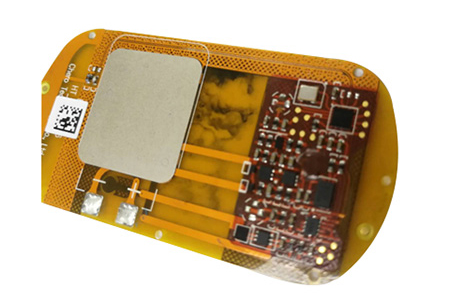

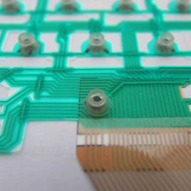

- Membrane Switches Membrane switches, also known asmembrane keypads, are the integral seal structure comprised of multi-layer circuit boards. The membrane keypad combines the key switch, panel and indication graphic interface.

Tayang has nearly 400 R&D personnel, over half of whom are senior developers with over 10 years of working experience. More than 70% of workers at the production line have worked in silicone rubber industry for more than 5 years. Our independent production base is equipped with complete production equipment, including silicone rubber molding machines, multi-color printers, automation coating workshop, efficient assembly line, etc. which allow us to provide you with one-stop silicone products customization solution from design to manufacturing.