- Home

- Products

- Silicone Rubber Compression Molding

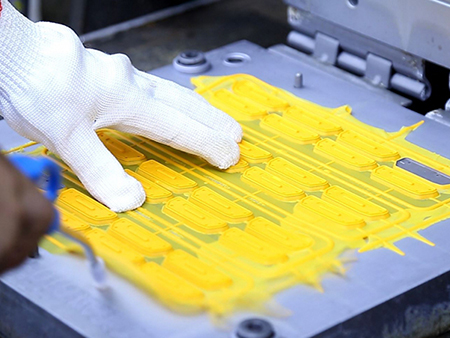

Silicone Rubber Compression Molding

With nearly 30 years of experience,Tayang has the expertise necessary for providing an outstanding silicone rubber compression molding service. We offer small-volume silicone rubber compression molding products, including keypads, gaskets, key fobs, decorated plastic parts and more. We have successfully served customers in a variety of industries, including automobile, consumer electronics, household appliances, medical and more.

To ensure the silicone rubber finished products are qualified, Tayang strictly controls the mold quality. CNC machine centers and EDM machines are utilized to produce aluminum molds and control the precision. Compared to the liquid injection molding, the mold development time for compression molding is shorter, which is ideal for small-volume runs and delivers a faster product update period and lower-cost production.

-

-

Advantages

- low mold cost

- short L/T

- short mold switching time → suitable for small batch production or samples demand

- continuously producing different color & raw material parts without switching feeding system

More

-

-

Silicone Rubber Compression Molding Production

117 compression molding machines are equipped in our workshop, ensuring we easily meet your volume production requirements for a variety of silicone rubber products.

Products that are compression molded cannot be directly used until they are processed by a series of other procedures. Take the production of silicone rubber keypad assembled with plastic buttons as an example:

- plastic buttons

- injection

- 5 colors printing on reverse side

- varnish printing

- fool-proof mark printing

- punching

-

-

keypad

- roll mixing

- compression overmolding with pills

- de-flashing

- HVE

- automatically glue dispensing on keypad

- assembling

- AOI

- packing

The mixing machine first mixes the pigment and raw silicone rubber, then the compression overmolding the keypad shape with pills. After removing the over flashes, they are treated by HVE for better glue dispensing. Afterwards, both the keypad and printed plastic buttons are assembling with glue by positioning jig. Then, they are packing after passing automatic optic inspector of printing logos.

More - plastic buttons

- width ≤ 0.25mm

- thickness ≤ 0.08mm

- no jagged edge

- light: 860~1600 LUX

- distance: 30~35cm

- starring time: 5 seconds

- eye inspection Angle: The line of sight is 90°from the inspection surface.

- D: the area covered by this diameter may be the same area of different shapes.

- N: number

- W: width

- L: length

| Defective | Acceptable level of compression molding silicone rubber surface class X | |||

| A | B | C | D | |

| different color dot | D≤0.20mm N≤2 d istance>50mm |

D≤0.30mm N≤2 distance>50mm |

D≤0.40mm N≤2 distance>50mm |

acceptable without functional failure |

| similar color dot | D≤0.25mm N≤2 distance>50mm |

D≤0.35mm N≤2 distance>50mm |

D≤0.45mm N≤3 distance>50mm |

acceptable without functional failure |

| slight scratch | W≤0.08mm L≤1.5mm N≤1 |

W≤0.08mm L≤2.5mm N≤1 |

W≤0.15mm L≤8mm N≤2 |

acceptable without functional failure |

| scratch | N=0 | W≤0.08mm L≤1.5mm N≤1 |

W≤0.15mm L≤5mm N≤1 |

acceptable without functional failure |

- Add.:

Xin Guang Road, Jin He Industrial District, Zhang Mutou Town, Dongguan City, Guangdong Province.

- Tel.:

+86-769-87197979