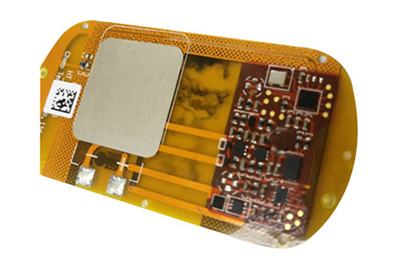

Bluetooth Smart Patch for Temperature & Cardiac Monitoring

The client cooperated with Peking Union Medical College to develop the Bluetooth smart patch. But when they sent the design drawing to several silicone product manufacturers in Guangdong and Zhejiang Province, these manufacturers all replied the structure of this product can’t work. Finally, the client found Tayang. Our R&D center has used following solution to realize the mass production of the Bluetooth smart patch.

-

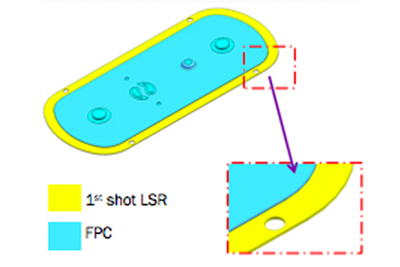

IQC-passed FPC(flexible printed circuit)

-

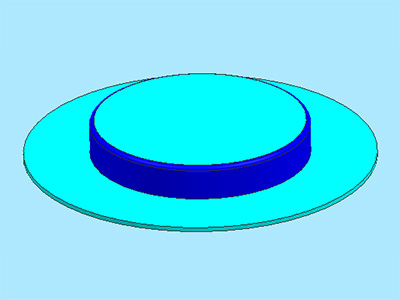

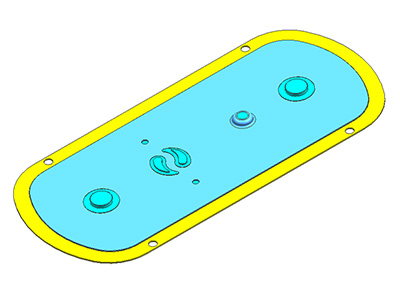

1st LSR injection for bottom covered part(FPC imbedded)

-

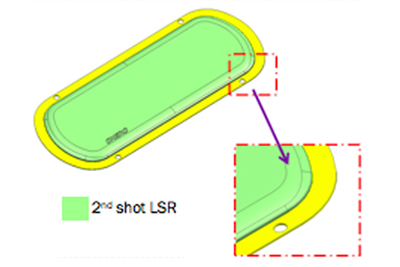

2nd LSR injection for upper covered part(FPC+LSR imbedded)

-

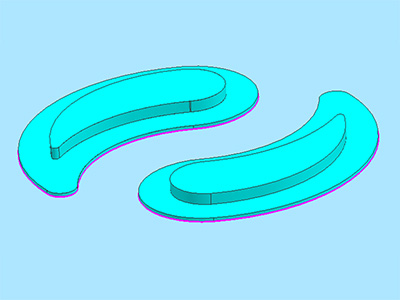

de-flashing and spraying touch feeling oil

- Low curing temperature LSR TSN-S040A/B chosen

- Low temperature touch feeling oil BND-C011D chosen

After twice injection, no LSR covers the 6 metal contacts, and no damaged contact is allowed.

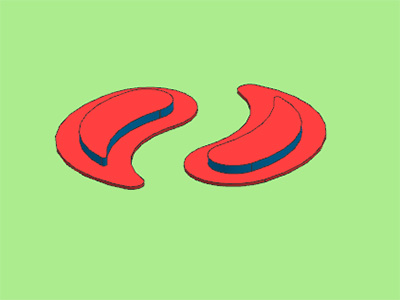

metal contact

metal contact

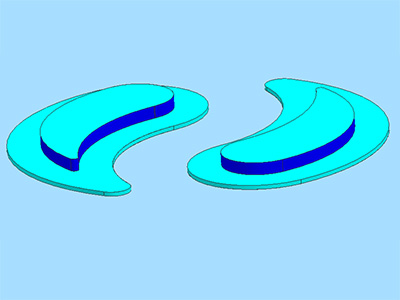

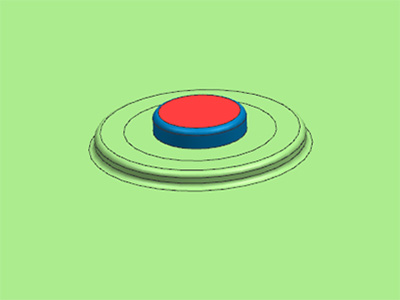

To prevent that mold damages 6 contacts, Design of 0.2mm gap in deep blue areas.

To prevent that too thick LSR flashes causes breaking after de-flashing, the around purple flash structure is necessary.

For no air trap, all the purple corner change to 0.3mm radius.

- The missing of part, falling off of component, exposing of FPC broad, and occurring of large raised or recessed area are not allowed.

- Dimension tolerance follows DIN ISO 3302-1 CLASS M1

- LSR remaining flash width ≤0.08mm; no breaking or serrated flash accepted

- Air trap of LSR ≤ 0.30mm²

- No LSR covers the touch points of FPC, or function fails.

- Add.:

Xin Guang Road, Jin He Industrial District, Zhang Mutou Town, Dongguan City, Guangdong Province.

- Tel.:

+86-769-87197979